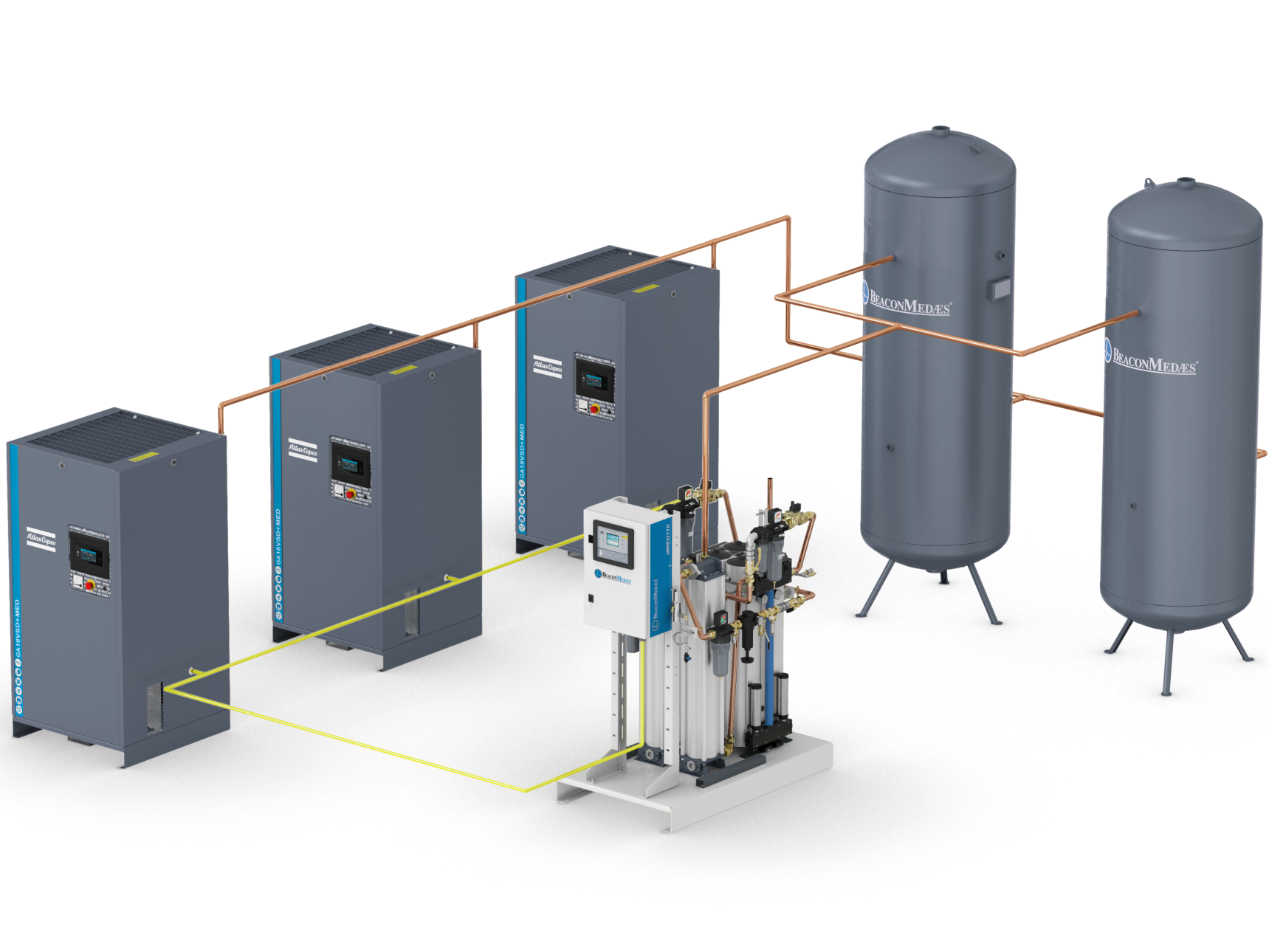

BeaconMedæs and Atlas Copco have further developed a 4th generation of dMED air purification system (dryer) incorporated in all Medical Air Plant. We proudly introduce the highest specification system to the market offering variable speed drive and oil free technologies to suit the ever hanging energy and sustainability needs.

Function

The field of patient care requires ultra clean, purified, medical air delivered to operating theatres and hospital beds with absolute reliability. A hospital’s medical air supply is a vital life support service, maintaining respiration of the critically ill during mechanical ventilation.

Compressors

The highest specification of compressor is recommended for the demanding medical environment, where frequent stop/starting and cycling of compressors is common. mAIR incorporates Atlas Copco’s GA-MED screw compressor.

As a hospitals flow demand varies throughout the day we can now offer Variable Speed Drive (VSD+) screw compressors. Matching the speed of the compressor exactly to the demanded flow at any given time, this provides significant energy savings.

Air Purifier and Dryer

The dMED includes a hopcolite catalyst as standard, so we can guaranty carbon monoxide levels beneath those stated in the European Pharmacopeia monograph, even in high urban areas.

Controller

The ES-MED central controller can be connected to the hospitals LAN computer network, enabling live status of the plant to be monitored from any PC terminal including details of system alarms, run hours, pressure of supply, dewpoint level etc.